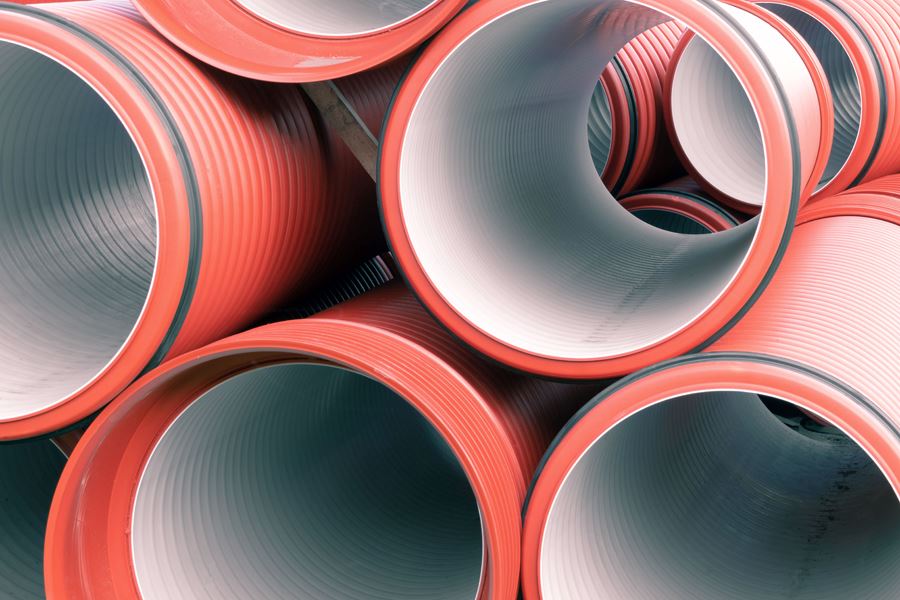

PVC

PVC (polyvinyl chloride) is one of the most widely used thermoplastic materials. PVC is normally divided into two different categories due to its physical properties: rigid (hard) and soft PVC.

The environmental impact of PVC is primarily associated with emissions of harmful organic chemicals throughout the production chain, the potential use of hazardous additives, and challenges related to waste management. There is ongoing development towards products and production processes that are less harmful to the environment and human health. In this respect, the EU has made significant progress; however, in other parts of the world, development has been slower.

Improvements in the environmental performance of PVC products include the replacement of heavy metal-based stabilisers, such as lead (Pb) and cadmium (Cd), which reduces the risk of spreading harmful chemicals during the recycling of PVC. Soft PVC also contains plasticisers, and there has been a shift away from traditionally hazardous phthalates towards plasticisers that are less harmful to human health.

How does the Nordic Swan Ecolabel contribute?

In general, Nordic Ecolabelling restricts the use of PVC in products where environmentally preferable alternatives that fulfil the same function are available. Nordic Swan Ecolabel requirements focus on the following:

- Prohibiting or restricting PVC in many Nordic Swan Ecolabel product groups due to health and environmental concerns.

- Prohibiting PVC in products with a short lifespan, such as packaging, as current waste management systems do not sort PVC for material recycling.

Allowing PVC in certain product groups where it is required for specific functions and where developments in the PVC industry have led to improved environmental performance over the life cycle of PVC. In such cases, requirements related to production technology, additives, feedstock (recycled or bio-based), and waste management apply.

Environmental background

Globally, three different cell technologies (mercury, diaphragm, and membrane) are used in the production of chlorine gas for PVC production. These technologies may give rise to emissions of halogenated compounds and other substances, such as sulphates, sulphites, and heavy metals, to air and wastewater.

- The mercury cell technology (still used in some plants outside Europe) is a significant source of environmental pollution, as mercury can contaminate air, water, and waste.

- For plants using the diaphragm method, emissions of asbestos to the surrounding environment may occur, and there may also be occupational exposure risks.

- For the membrane method, there may be emissions of poly- and perfluoroalkyl substances (PFAS).

Alternative stabiliser systems for rigid PVC, replacing lead (Pb) and cadmium (Cd), include in particular calcium–zinc-based formulations. PVC compounds containing these stabilisers now account for almost the entire European market for new PVC. Since 2007, the PVC industry in the EU has ceased the use of cadmium-based stabilisers, and since 2016 the use of lead-based stabilisers. However, PVC production outside the EU may still involve the use of cadmium and lead.

Plasticisers used in soft PVC are not bound to the polymer; they can migrate out of the material, meaning that PVC products can be a source of harmful chemicals to humans and the environment. Phthalates of particular concern include DEHP, BBP, DBP, and DIBP.

A finished soft PVC product may contain up to 40 per cent plasticisers. Today, new plasticisers are being developed and used to replace phthalates that have raised concerns due to their reproductive and endocrine-disrupting effects.

The industry has moved towards replacing hazardous low-molecular-weight phthalates (such as DEHP) with high-molecular-weight phthalates, such as DINP and DIDP, or other plasticisers. These substances are not classified as substances of very high concern under REACH; however, they are subject to use restrictions under certain European Commission regulations, particularly with regard to children’s toys and childcare articles.

PVC recycling systems are currently under development across various product areas. Nordic Ecolabelling is therefore assessing the feasibility of introducing requirements related to recycling.

Modern incineration plants in Europe operate with high efficiency, and emissions of unwanted chemicals associated with, for example, PVC, such as polycyclic aromatic hydrocarbons (PAHs), benzo[a]pyrene, dioxins, and furans, have been significantly reduced.

Nevertheless, not all Nordic countries permit the incineration of used PVC due to the extensive air pollution control measures required and the resulting waste generated from the neutralisation of flue gases. Denmark has waste legislation stipulating that all PVC must be sorted for material recycling and, if not recycled, must be sent to landfill.